Create Date: September 26, 2024

Last Modified Date: January 15, 2025

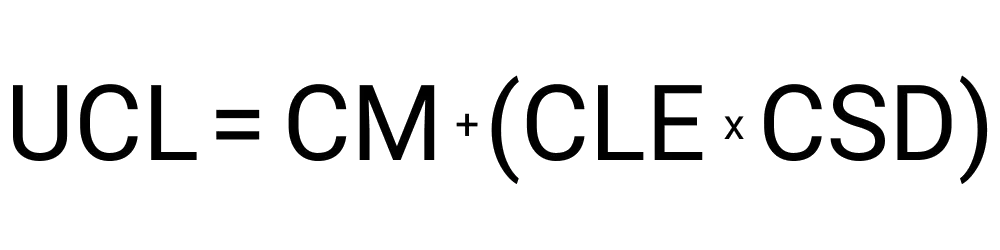

Calculating the upper control limit can be done with the following variables:

When you use this tool you will get two different results. First, you will see your upper control limit value. This is the highest acceptable value for your specific situation. Aside from that, you will get your lower control limit. Which is essentially the same thing in concept, but it is referring to the lowest acceptable value based on your entry.

Finding the upper control limit value can be done with a bit of work, or by simply using this tool. Plugging in a few values into this tool can make calculating the upper control limit easier than ever. The steps involved with using this tool include:

A coffee shop wants to ensure its baristas pour consistent amounts of coffee into cups to maintain quality and customer satisfaction. The shop uses a process control chart to monitor the volume of coffee poured into medium-sized cups. The control mean, or average, pour amount is 350 ml and the standard deviation is 5 ml. We can use this tool to determine the UCL. We can enter 350 into the control mean field, 5 into the control standard deviation field, and leave the control limit to evaluate as 3. If we wanted to allow for more than 3 standard deviations from the mean we can change this number to reflect that amount, but we are fine with 3 in this situation. We can now hit calculate and get a UCL of 365 ml and a LCL of 335 ml.

The UCL helps identify abnormal variations in a process, which could indicate potential problems. By staying within the limits, you can ensure consistent quality and performance.

If your process exceeds the UCL, it indicates an out-of-control condition. Investigate the root cause of the variation and take corrective action to bring the process back within control.